[ border_color=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” ][ spacing=”” target=”_self” border_color=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” border_sizes_top=”0″ border_sizes_bottom=”0″ border_sizes_left=”0″ border_sizes_right=”0″ ]

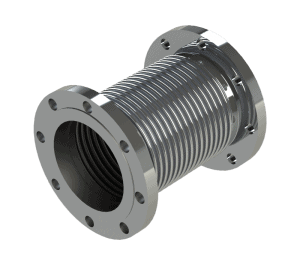

Bellows, in general, are used as a kind of connector. They are very strong, yet flexible, and they need to be able to withstand very intense conditions. Iron ore usually melts at around 2,700 degrees Fahrenheit. Steel, on the other hand, has a melting point of 2,500 degrees Fahrenheit. The material chosen for a bellow depends on the job and conditions that the bellow must withstand.

Bellows, in general, are used as a kind of connector. They are very strong, yet flexible, and they need to be able to withstand very intense conditions. Iron ore usually melts at around 2,700 degrees Fahrenheit. Steel, on the other hand, has a melting point of 2,500 degrees Fahrenheit. The material chosen for a bellow depends on the job and conditions that the bellow must withstand.

Expansion joints are typically used in a piping system. Pipe expansion joints absorb thermal expansion, or terminal movement. This is done when the use of expansion loops is not practical or desired. Expansion joints are available in various shapes and materials. Metal bellows, high pressure expansion joints, exhaust bellows, and even custom bellows are all different types that are available for a multitude of different jobs and applications.

Warning Signs of Failure

Plants that frequently use expansion bellows typically want to have ways to monitor them so that when a problem does occur, it can be quickly fixed. There is typically an orange top on an expansion joint, and when that top pops up, it is an indication that there is a leak in the bellow. This is usually the best way to detect failure for expansion bellows. If leakage is not detected early enough, major consequences can ensue.

What Can Cause Bellows Expansion Joints to Fail?

There are several different kinds of damage to a bellow that can cause it to fail. The first type is shipping and handling damages. Improper stacking of packages, being struck by another heavy object, or dropping can all damage the product while in transportation. If the package is mishandled, denting or gouging can happen, and the bellow will be nonfunctional.

The second most common type of damage to cause expansion joins to fail is when they are being installed. For example, if the bellow is installed in the incorrect direction of intended use or placed in the wrong location, it is sure to fail. As stated previously, bellows are produced for specific jobs, so if they are not placed in the correct location, operation will be dysfunctional.

There you have it. Bellows expansion joints are very helpful in piping systems. You want to make sure to replace them right away if they are leaking or damaged in some other way. Inspect them upon arrival to check for damages, and ensure that they are installed correctly to serve their proper function.